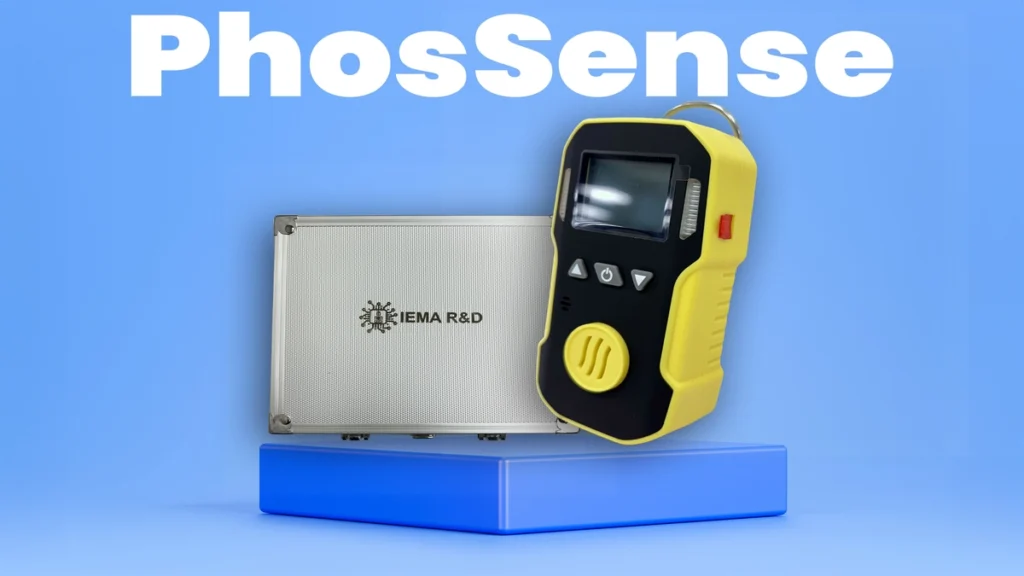

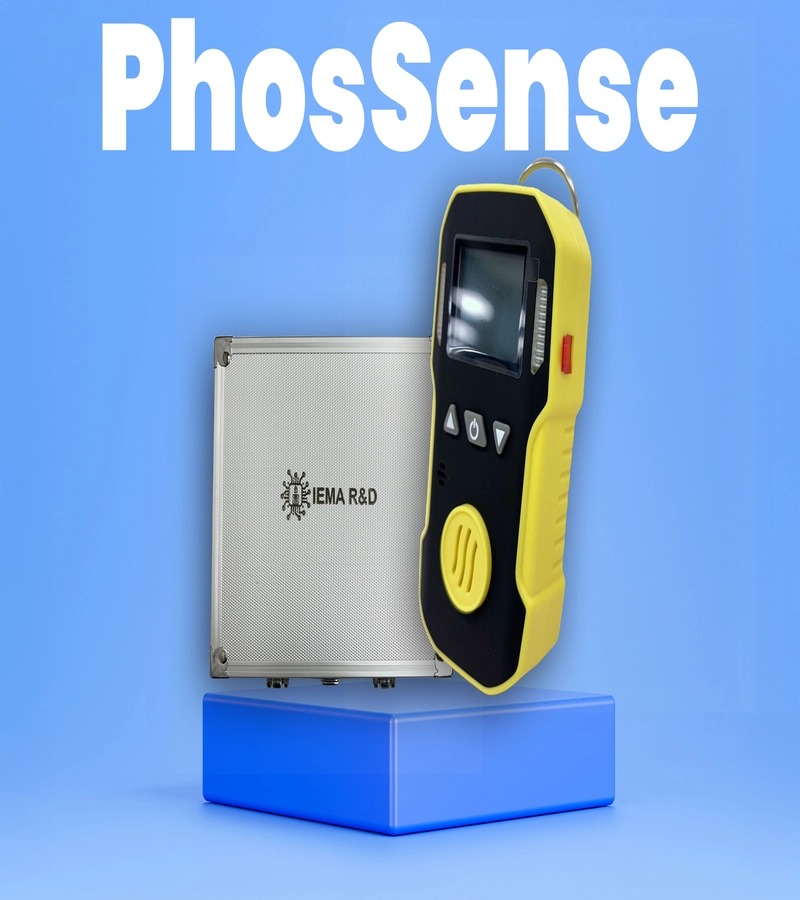

Advanced MCU control with low power consumption

Advanced MCU control ensures efficient, low-power operation, extending battery life while maintaining high performance in embedded systems and IoT devices.

Adjustable low and high alarm levels

MCU control optimizes power usage with sleep modes, dynamic clock scaling, and efficient algorithms, enabling longer battery life in portable and IoT devices.

Low battery indication

Low battery indication alerts users via LED, sound, or display when power is critically low, ensuring timely recharging or replacement to prevent shutdown.

Visual and audible alarm with vibration

Visual (LED/flashing lights), audible (beep/siren), and vibration alerts ensure immediate hazard notification, enhancing safety in noisy or low-visibility environments.

Password management to avoid wrong operation

Password protection prevents unauthorized access, reducing accidental or incorrect operations while ensuring secure and controlled system usage in critical applications.